It all started in the fall of 2020. In the midst of the Covid outbreak and surfing on the success of the Outremer 55, the first plenary meetings took place with creative workshops being held in parallel to imagine the successor of the Outremer 51.

Let’s go back a few months

Following multiple exchanges with the Outremer community, which is very committed and always pushing us to improve (customers and owners), we identified strong expectations. After millions of miles sailed on 51’s over the last ten years, it was time to answer them…

The Outremer 51, a true reference in blue-water sailing, set the bar very high!

With Gunboat joining the Grand Large Yachting group in 2016, Outremer took a step forward in terms of quality requirements. New engineering resources and innovative materials enabled us to achieve an unprecedented displacement-habitability compromise, thus improving the marine capabilities and quality of life on board our catamarans.

Everything moved right into place to help us define a worthy successor to the 51′.

Moving on to the design phase…

To define this new model, we brought together the dream team that made the 55′ a success: VPLP, Patrick Le Quément and Darnet Design, and included a group of future owners in the process. Although inspired by the innovations of the Outremer 55, the Outremer 52 was the result of a thorough reflection, punctuated by a lot of customer feedback.

Through a 360° rendering, we considered all aspects related to life on board and the use of the boat (male-female parity, ecological footprint, modularity…).

The layout plan went through several versions and evolved over time to reach the ideal compromise.

The boat starts to take shape

There is a lot of back and forth between the VPLP team, Darnet Design, Patrick Le Quément and the Outremer Design Office before validating the final design, the structural concept and the technical realization. Only once this phase is complete can the manufacturing of the hull and deck molds be launched.

Creating the molds

In order to ensure an optimal sequence of the manufacturing cycle, the hull shapes are launched first, followed by the deck shapes, slightly delayed during the studies with our partners, in order to have the production tools at the right time.

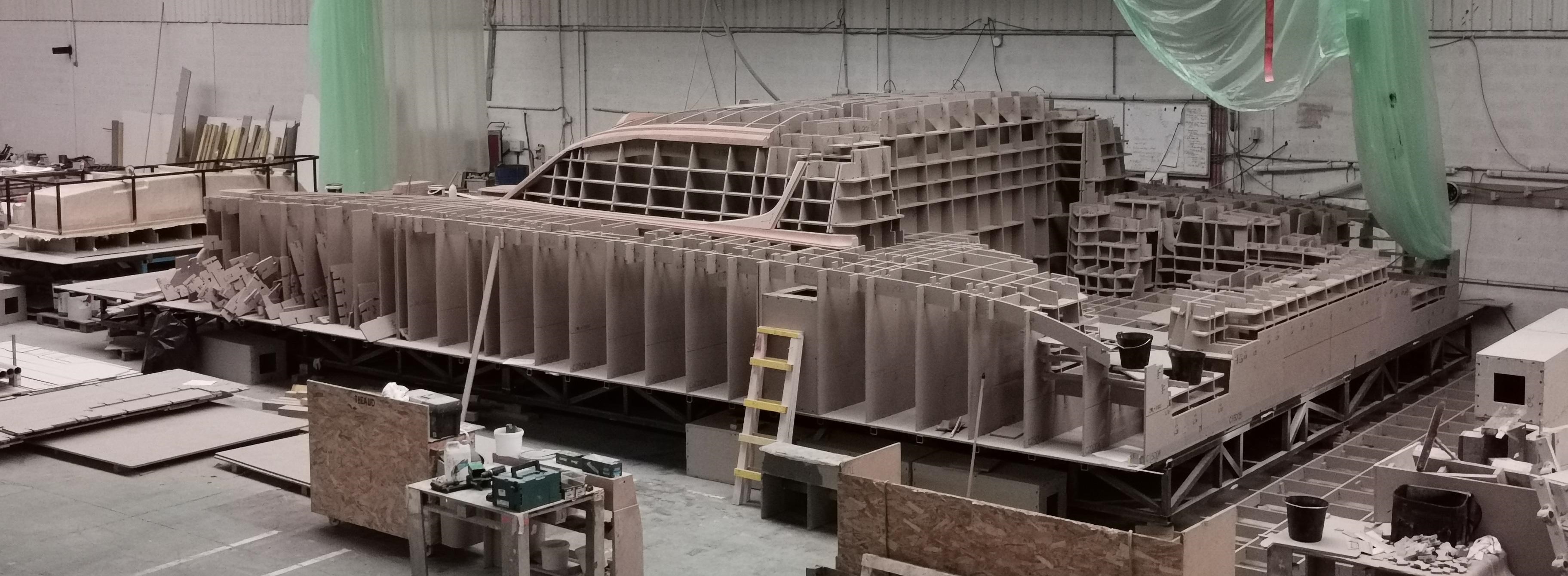

Following precisely the plans provided by the architect, a wooden structure to scale 1 is built to the shape of the deck. The most complex shapes, such as the roof handrails or the drainpipes, are machined in foam using a numerically controlled machine. This part is called the master and will serve as a negative for the construction of the deck mold.

December 2021, creation of the scale 1 model of the deck plan

During the manufacturing of the hull mold, we finalized the deck plan with a scale 1 model to validate the last details of ergonomics and launch the production of the deck mold.

A new building dedicated to the 52’ is finished just in time to receive the hull molds and to finally launch the first lamination.

A race against the clock had begun, with the objective of presenting the boat at the La Grande Motte International Multihull boat show 2023.

June 1, 2022, infusion of the first hull

After the unloading of the new molds, which you could follow on our Instagram account, discover below the different steps of infusion – molding:

- Cleaning of the mold then waxing to facilitate the demolding

- Spraying Gel Coat inside the mold

- Laminating the anti-osmosis barrier in vinylester resin

- Positioning of the fabrics according to a precise plan with different weights and thicknesses

- Positioning of the core materials

- Laying of the inner sandwich fabrics

- Installation of the vacuum peripherals

- Vacuum test

And finally the resin infusion.

It is always impressive to see the resin impregnate over 140m2 of fabric in less than an hour!

Once the molding stage is over, the partitions are placed and laminated to the hull, to create a monoblock assembly that will allow for perfect rigidity of the structure.

The first lamination is a full vinylester protective barrier. The structural partitions are in carbon/divinycell/epoxy and the auxiliary partitions for the watertight compartments in divinycell/glass/polyester or epoxy wood.

The stringers and couples become a monobloc structure that gives the boat its exceptional rigidity.

This means that the boat structure will be both strong and durable, with no creaking and minimal distortion.

Next comes the unmolding of the hulls and deck.

The Outremer 52 begins to reveal its shape…

Once the structure is ready, the “systems” and “carpentry” teams take over with the installation of:

- plumbing and electrical circuits, as well as a custom-made aluminum floor support structure. Each connection element is labeled and easily accessible to make maintenance at sea easier.

- engines and tanks

- furniture elements. All the furniture elements are isolated from the structure thanks to a flexible connection that will absorb the micro-movements. Thus the boat is totally silent in all conditions.

In November 2022, hulls and deck become one!

A major and delicate step in the construction of an Outremer catamaran: decking consists of installing the boat’s deck on the hulls in such a way as to create a perfect joint, ensuring a solid and durable connection.

In February 2023, the first Outremer 52 touches water in La Grande-Motte (under the snow!)

It was another proud moment for the hundreds of collaborators who worked on the project.

Do you have a sailing project and would you like to preview this brand new model at the International Multihull Boat Show in La Grande-Motte, from April 12 to 16? Please fill in this online form and a representative will get back to you. If you wish to simply tour a boat, book your timeslot here.

Continue navigation

Spotlight on the Outremer 45

With more than 100 boats delivered over the last 10 years, the Outremer 45 has confirmed its status as a legendary model within the Outremer shipyard.

A look back in pictures at the Outremer Cup 2025!

Friendly regattas, time together ashore, an evening with all the participants, and perfect weather… everything came together to make this edition truly unforgettable!